For Second Year in a Row, CNBC Names North Carolina as America’s Top State for Business

CNBC has named North Carolina as America’s Top State for Business in 2023 for the second...

Popular Searches

The people of North Carolina make this place special. And our state’s quality of life is keeping them here and helping it grow.

North Carolina is at the forefront of innovation and change. Our state’s renewable energy economy is why companies like Duke Energy are making their mark here.

North Carolina’s education system provides a competitive edge – top talent is being trained here, and they’re staying here.

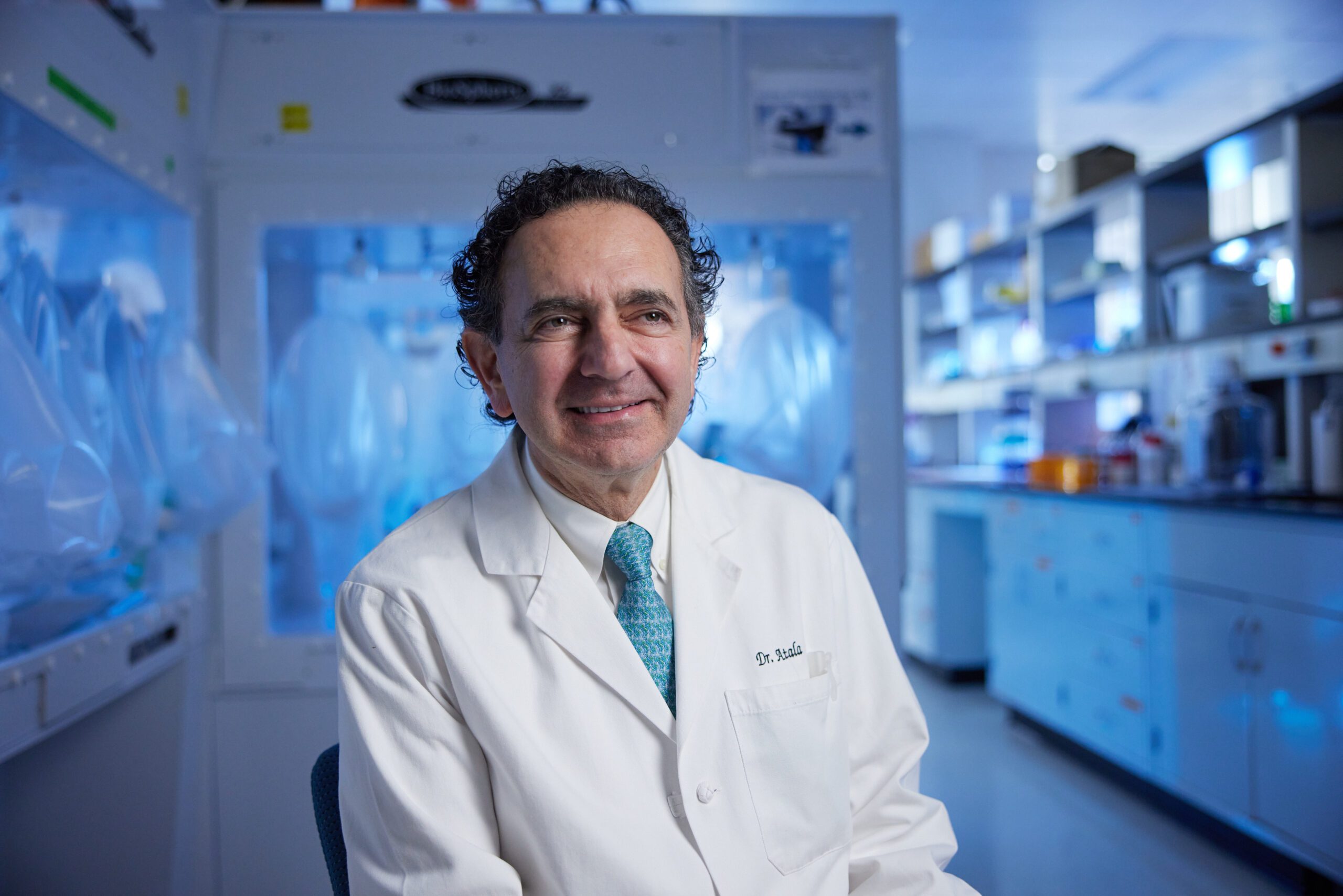

The last two decades North Carolina has been the state with the largest growth in the biotechnology sector.

CNBC has named North Carolina as America’s Top State for Business in 2023 for the second...

Largest manufacturing workforce in the Southeast & the lowest corporate income tax in the US. No wonder North Carolina is where businesses thrive.

North Carolina pioneered innovation in workforce, from the nation’s first public university to launching the first customized training program.

As the costs of fossil fuels rise to the highest levels in decades, businesses are seeking cost effective and sustainable energy solutions.